English

English 简体中文

简体中文  Esperanto

Esperanto  Afrikaans

Afrikaans  Català

Català  Cymraeg

Cymraeg  Galego

Galego  繁体中文

繁体中文  Latviešu

Latviešu  icelandic

icelandic  ייִדיש

ייִדיש  беларускі

беларускі  Hrvatski

Hrvatski  Kreyòl ayisyen

Kreyòl ayisyen  Shqiptar

Shqiptar  Malti

Malti  lugha ya Kiswahili

lugha ya Kiswahili  አማርኛ

አማርኛ  Bosanski

Bosanski  Frysk

Frysk  ភាសាខ្មែរ

ភាសាខ្មែរ  ქართული

ქართული  ગુજરાતી

ગુજરાતી  Hausa

Hausa  Кыргыз тили

Кыргыз тили  ಕನ್ನಡ

ಕನ್ನಡ  Corsa

Corsa  Kurdî

Kurdî  മലയാളം

മലയാളം  Maori

Maori  Монгол хэл

Монгол хэл  Hmong

Hmong  IsiXhosa

IsiXhosa  Zulu

Zulu  Punjabi

Punjabi  پښتو

پښتو  Chichewa

Chichewa  Samoa

Samoa  Sesotho

Sesotho  සිංහල

සිංහල  Gàidhlig

Gàidhlig  Cebuano

Cebuano  Somali

Somali  Тоҷикӣ

Тоҷикӣ  O'zbek

O'zbek  Hawaiian

Hawaiian  سنڌي

سنڌي  Shinra

Shinra  Հայերեն

Հայերեն  Igbo

Igbo  Sundanese

Sundanese  Lëtzebuergesch

Lëtzebuergesch  Malagasy

Malagasy  Yoruba

Yoruba  Español

Español  Português

Português  русский

русский  Français

Français  日本語

日本語  Deutsch

Deutsch  tiếng Việt

tiếng Việt  Italiano

Italiano  Nederlands

Nederlands  ภาษาไทย

ภาษาไทย  Polski

Polski  한국어

한국어  Svenska

Svenska  magyar

magyar  Malay

Malay  বাংলা ভাষার

বাংলা ভাষার  Dansk

Dansk  Suomi

Suomi  हिन्दी

हिन्दी  Pilipino

Pilipino  Türkçe

Türkçe  Gaeilge

Gaeilge  العربية

العربية  Indonesia

Indonesia  Norsk

Norsk  تمل

تمل  český

český  ελληνικά

ελληνικά  український

український  Javanese

Javanese  فارسی

فارسی  தமிழ்

தமிழ்  తెలుగు

తెలుగు  नेपाली

नेपाली  Burmese

Burmese  български

български  ລາວ

ລາວ  Latine

Latine  Қазақша

Қазақша  Euskal

Euskal  Azərbaycan

Azərbaycan  Slovenský jazyk

Slovenský jazyk  Македонски

Македонски  Lietuvos

Lietuvos  Eesti Keel

Eesti Keel  Română

Română  Slovenski

Slovenski  मराठी

मराठी  Srpski језик

Srpski језик

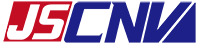

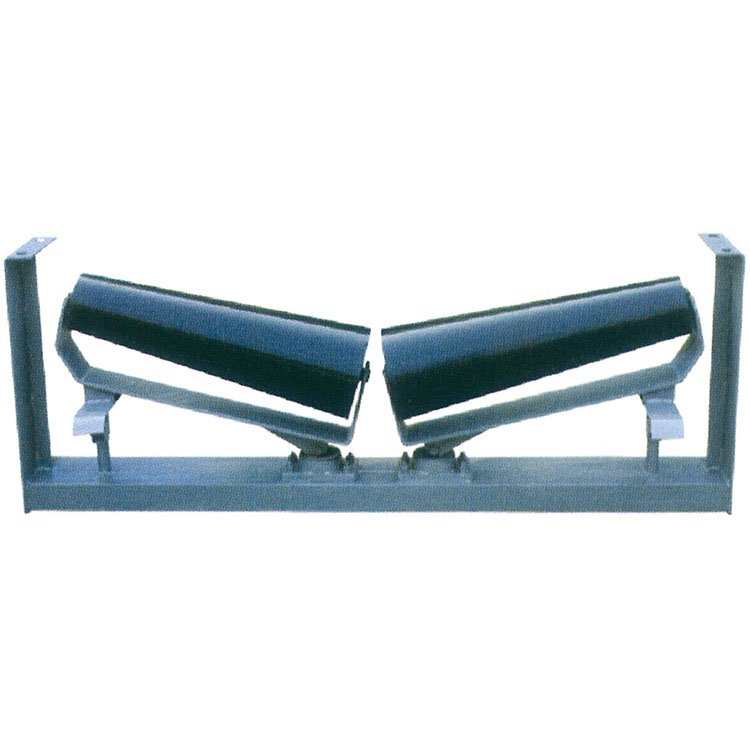

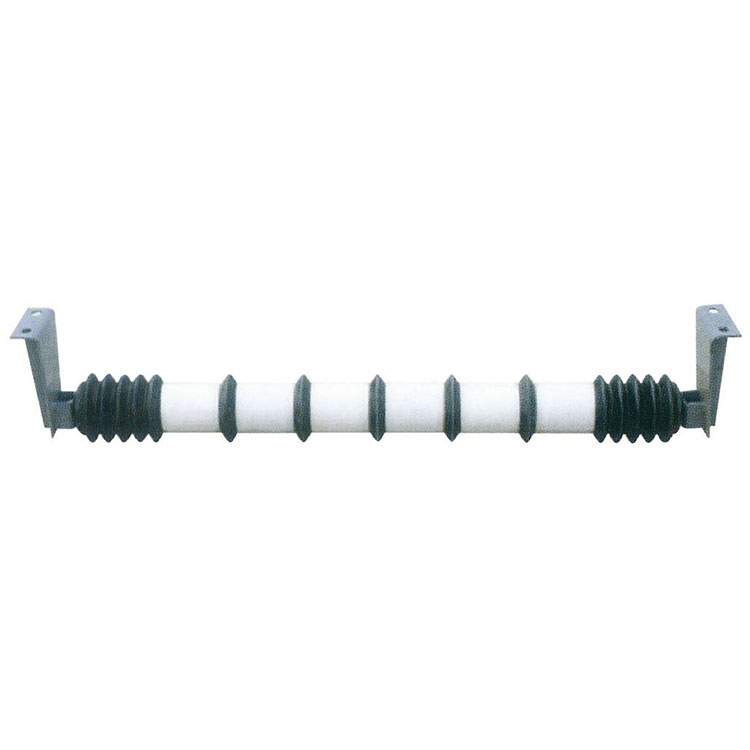

Bearing Rollers

The bearing rollers manufactured by Wuyun use high-quality, thick-walled special welded pipes for rollers, which have the characteristics of thick pipe walls and strong load-bearing capacity. The outer weld seam is smooth and flat, and the outer circle runout is small, ensuring smooth belt operation and low noise. Perfectly solve the belt jumping problem for you.

Send Inquiry

The bearing rollers manufactured by Wuyun use high-quality, thick-walled special welded pipes for rollers, which have the characteristics of thick pipe walls and strong load-bearing capacity. The outer weld seam is smooth and flat, and the outer circle runout is small, ensuring smooth belt operation and low noise. Perfectly solve the belt jumping problem for you.

The roller adopts a fully sealed structure, and the bearing assembly adopts a high-precision bearing chamber and high-quality bearings dedicated to the roller. It has the advantages of exquisite structure, low noise, long life, and reliable performance. It is the best choice for advanced belt conveyor systems.

We provide you with more favorable prices and super cost-effectiveness, timely and accurate quotations, and fast delivery speed. Users from all over the world are welcome to purchase products from China.

During the use of load-bearing rollers, if you can pay attention to the following points, it will be very helpful to improve the service life and operating efficiency:

A. Ensure the good working effect of the return cleaner. Once the stain on the return belt adheres to the load-bearing rollers, the outer circle of the roller will no longer be uniform, causing the belt to jump, thereby damaging the roller bearing.

B. Please use special buffer rollers or buffer beds in areas that receive direct impact from materials to slow down the impact force.

C. The material on the belt should not exceed the design load to avoid material overflowing the belt and damaging the rollers.

D. When the roller makes abnormal noise or metal friction sound, the roller should be inspected and maintained, and the damaged bearings or seals should be replaced.

|

ProductName |

Specifications and models |

D |

d |

L |

b |

h |

f |

|

Bearing Rollers |

89*250 |

89 |

20 |

250 |

14 |

6 |

14 |

|

Bearing Rollers |

89*315 |

89 |

20 |

315 |

14 |

6 |

14 |

|

Bearing Rollers |

89*600 |

89 |

20 |

600 |

14 |

6 |

14 |

|

Bearing Rollers |

89*750 |

89 |

20 |

750 |

14 |

6 |

14 |

|

Bearing Rollers |

89*950 |

89 |

20 |

950 |

14 |

6 |

14 |

|

Bearing Rollers |

108*380 |

108 |

25 |

380 |

18 |

8 |

17 |

|

Bearing Rollers |

108*465 |

108 |

25 |

465 |

18 |

8 |

17 |

|

Bearing Rollers |

108*1150 |

108 |

25 |

1150 |

18 |

8 |

17 |

|

Bearing Rollers |

108*1400 |

108 |

25 |

1400 |

18 |

8 |

17 |