English

English 简体中文

简体中文  Esperanto

Esperanto  Afrikaans

Afrikaans  Català

Català  Cymraeg

Cymraeg  Galego

Galego  繁体中文

繁体中文  Latviešu

Latviešu  icelandic

icelandic  ייִדיש

ייִדיש  беларускі

беларускі  Hrvatski

Hrvatski  Kreyòl ayisyen

Kreyòl ayisyen  Shqiptar

Shqiptar  Malti

Malti  lugha ya Kiswahili

lugha ya Kiswahili  አማርኛ

አማርኛ  Bosanski

Bosanski  Frysk

Frysk  ភាសាខ្មែរ

ភាសាខ្មែរ  ქართული

ქართული  ગુજરાતી

ગુજરાતી  Hausa

Hausa  Кыргыз тили

Кыргыз тили  ಕನ್ನಡ

ಕನ್ನಡ  Corsa

Corsa  Kurdî

Kurdî  മലയാളം

മലയാളം  Maori

Maori  Монгол хэл

Монгол хэл  Hmong

Hmong  IsiXhosa

IsiXhosa  Zulu

Zulu  Punjabi

Punjabi  پښتو

پښتو  Chichewa

Chichewa  Samoa

Samoa  Sesotho

Sesotho  සිංහල

සිංහල  Gàidhlig

Gàidhlig  Cebuano

Cebuano  Somali

Somali  Тоҷикӣ

Тоҷикӣ  O'zbek

O'zbek  Hawaiian

Hawaiian  سنڌي

سنڌي  Shinra

Shinra  Հայերեն

Հայերեն  Igbo

Igbo  Sundanese

Sundanese  Lëtzebuergesch

Lëtzebuergesch  Malagasy

Malagasy  Yoruba

Yoruba  Español

Español  Português

Português  русский

русский  Français

Français  日本語

日本語  Deutsch

Deutsch  tiếng Việt

tiếng Việt  Italiano

Italiano  Nederlands

Nederlands  ภาษาไทย

ภาษาไทย  Polski

Polski  한국어

한국어  Svenska

Svenska  magyar

magyar  Malay

Malay  বাংলা ভাষার

বাংলা ভাষার  Dansk

Dansk  Suomi

Suomi  हिन्दी

हिन्दी  Pilipino

Pilipino  Türkçe

Türkçe  Gaeilge

Gaeilge  العربية

العربية  Indonesia

Indonesia  Norsk

Norsk  تمل

تمل  český

český  ελληνικά

ελληνικά  український

український  Javanese

Javanese  فارسی

فارسی  தமிழ்

தமிழ்  తెలుగు

తెలుగు  नेपाली

नेपाली  Burmese

Burmese  български

български  ລາວ

ລາວ  Latine

Latine  Қазақша

Қазақша  Euskal

Euskal  Azərbaycan

Azərbaycan  Slovenský jazyk

Slovenský jazyk  Македонски

Македонски  Lietuvos

Lietuvos  Eesti Keel

Eesti Keel  Română

Română  Slovenski

Slovenski  मराठी

मराठी  Srpski језик

Srpski језик

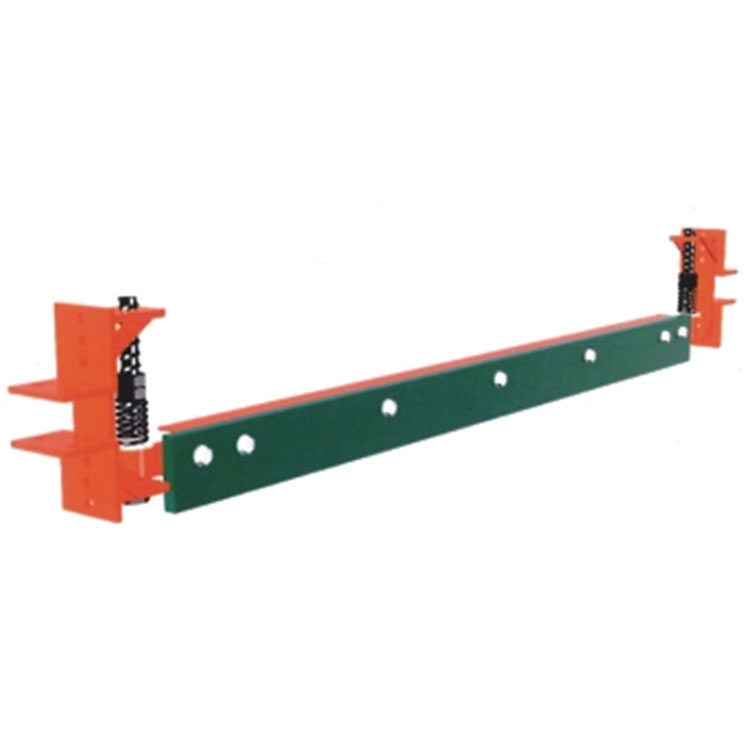

China Centering Device for Conveyor Divert Plow Manufacturers, Suppliers, Factory

We'll make each hard work to become excellent and excellent, and speed up our measures for standing from the rank of intercontinental top-grade and high-tech enterprises for Centering Device for Conveyor Divert Plow,Electric Actuated One Side Plow Unloader,Conveyor Diverter Plows Material Diversion Ploughs,Belt Conveyor Diverter Plow,V plough feeder, Welcome any inquiry to our firm. We're going to be glad to establish pleasant business interactions with you!

Centering Device for Conveyor Divert Plow, We have now won a good reputation among overseas and domestic clients. Adhering to the management tenet of "credit oriented, customer first, high efficiency and mature services", we warmly welcome friends from all walks of life to cooperate with us.

Hot Products

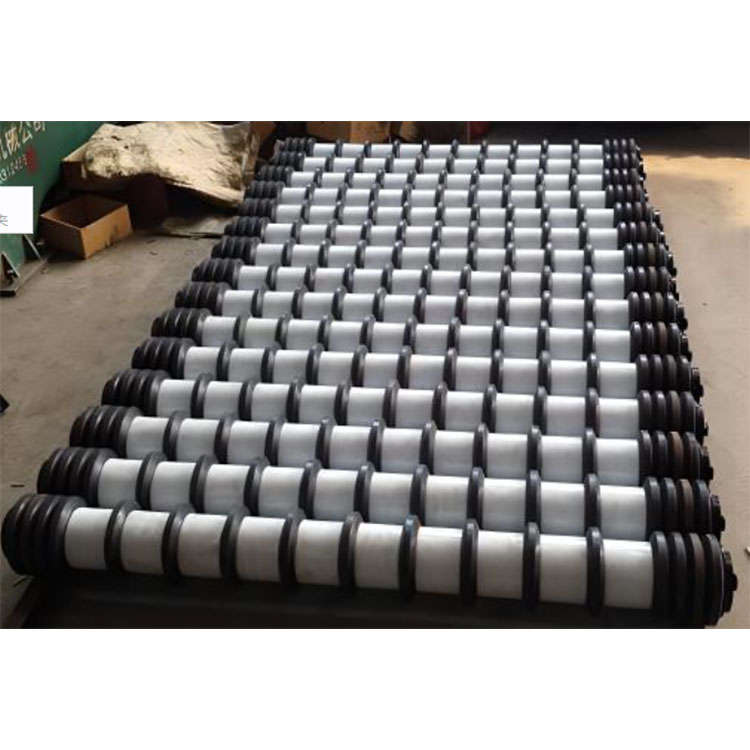

Ceramic Conveyor Idler

Ceramic conveyor idler are made of aluminum oxide. It is resistant to acid and alkali corrosion and is more suitable for conveying high-hardness materials. It is widely used in mining, sand and gravel, steel metallurgy, chemical industry, and other industries.Parallel Comb Idler

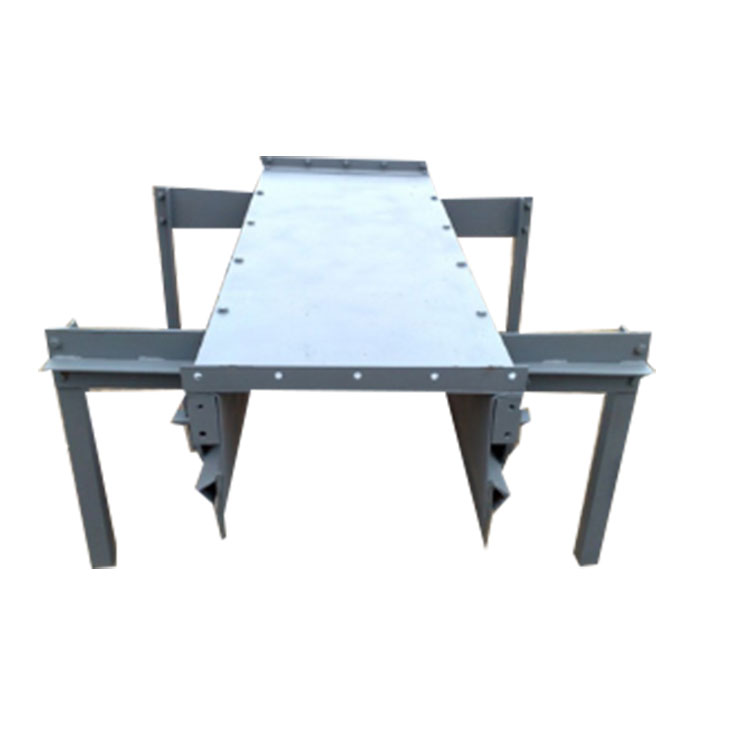

Parallel Comb Idler is one type of conveyor idler. It is made of high-frequency welded pipes, high-density nylon seals, comb-shaped rubber rings, spacers, bearings, and round steel. Parallel Comb Idler are mainly used to fix return belts of belt conveyors. The structural design has a self-cleaning function, which can effectively remove belt adhesive. It has the characteristics of low noise, thick tube wall, flexible rotation and low resistance.Double Sealed Conveyor Transfer Chute

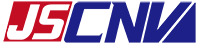

Double Sealed Conveyor Transfer Chute is mainly used at the head and tail of the belt conveyor to guide, prevent overflow and dust-proof materials. Double Sealed Conveyor Transfer Chute is composed of structural parts, holders, skirt panels, front curtains and rear curtains. The anti-overflow skirt adopts an integrated structure. The straight part prevents materials from overflowing and blocks most dust. The everted skirt plate is close to the conveyor belt to prevent all dust from escaping. In conjunction with a negative pressure dust removal system, a dust-free working environment can be achieved.Bearing Idler

Idlers are to conveyors as foundations are to buildings: constant, reliable support. Our bearing idler choosing quality metals and well-known brands bearings, interference fit between the shaft and the bearing for improved sealing, better stability and longer life. Conveyor Idler parts used Fully sealed structure, Bearings assembly adopts high precision bearing chamber and high-quality bearings for idlers. With beautiful structure, low noise, long life (more than 20,000 hours of service life) etc.Helix Idler

The helix steel column with the hard appearance of the helix idler has superior wear resistance and can cope with various hardness materials.Helix idler can automatically clean the belt and inhibit the material sticking to the surface of the idler.One-Line Cleaner

One-line cleaner is for the return belt cleaning. It is mainly used in front of the rear bend pulley and in front of the heavy vertical tensioning device of the belt conveyor. It can especially be used to clean the empty section of the two-way running belt. It has the characteristics of acid and alkali resistance, flame retardant and antistatic, high wear resistance, and does not damage the belt. The blade is made of high-strength polyurethane, the V-shaped design ensures belt cleanliness, and the automatic gravity design ensures automatic-compensation when the blade wears out.