English

English 简体中文

简体中文  Esperanto

Esperanto  Afrikaans

Afrikaans  Català

Català  Cymraeg

Cymraeg  Galego

Galego  繁体中文

繁体中文  Latviešu

Latviešu  icelandic

icelandic  ייִדיש

ייִדיש  беларускі

беларускі  Hrvatski

Hrvatski  Kreyòl ayisyen

Kreyòl ayisyen  Shqiptar

Shqiptar  Malti

Malti  lugha ya Kiswahili

lugha ya Kiswahili  አማርኛ

አማርኛ  Bosanski

Bosanski  Frysk

Frysk  ភាសាខ្មែរ

ភាសាខ្មែរ  ქართული

ქართული  ગુજરાતી

ગુજરાતી  Hausa

Hausa  Кыргыз тили

Кыргыз тили  ಕನ್ನಡ

ಕನ್ನಡ  Corsa

Corsa  Kurdî

Kurdî  മലയാളം

മലയാളം  Maori

Maori  Монгол хэл

Монгол хэл  Hmong

Hmong  IsiXhosa

IsiXhosa  Zulu

Zulu  Punjabi

Punjabi  پښتو

پښتو  Chichewa

Chichewa  Samoa

Samoa  Sesotho

Sesotho  සිංහල

සිංහල  Gàidhlig

Gàidhlig  Cebuano

Cebuano  Somali

Somali  Тоҷикӣ

Тоҷикӣ  O'zbek

O'zbek  Hawaiian

Hawaiian  سنڌي

سنڌي  Shinra

Shinra  Հայերեն

Հայերեն  Igbo

Igbo  Sundanese

Sundanese  Lëtzebuergesch

Lëtzebuergesch  Malagasy

Malagasy  Yoruba

Yoruba  Español

Español  Português

Português  русский

русский  Français

Français  日本語

日本語  Deutsch

Deutsch  tiếng Việt

tiếng Việt  Italiano

Italiano  Nederlands

Nederlands  ภาษาไทย

ภาษาไทย  Polski

Polski  한국어

한국어  Svenska

Svenska  magyar

magyar  Malay

Malay  বাংলা ভাষার

বাংলা ভাষার  Dansk

Dansk  Suomi

Suomi  हिन्दी

हिन्दी  Pilipino

Pilipino  Türkçe

Türkçe  Gaeilge

Gaeilge  العربية

العربية  Indonesia

Indonesia  Norsk

Norsk  تمل

تمل  český

český  ελληνικά

ελληνικά  український

український  Javanese

Javanese  فارسی

فارسی  தமிழ்

தமிழ்  తెలుగు

తెలుగు  नेपाली

नेपाली  Burmese

Burmese  български

български  ລາວ

ລາວ  Latine

Latine  Қазақша

Қазақша  Euskal

Euskal  Azərbaycan

Azərbaycan  Slovenský jazyk

Slovenský jazyk  Македонски

Македонски  Lietuvos

Lietuvos  Eesti Keel

Eesti Keel  Română

Română  Slovenski

Slovenski  मराठी

मराठी  Srpski језик

Srpski језик

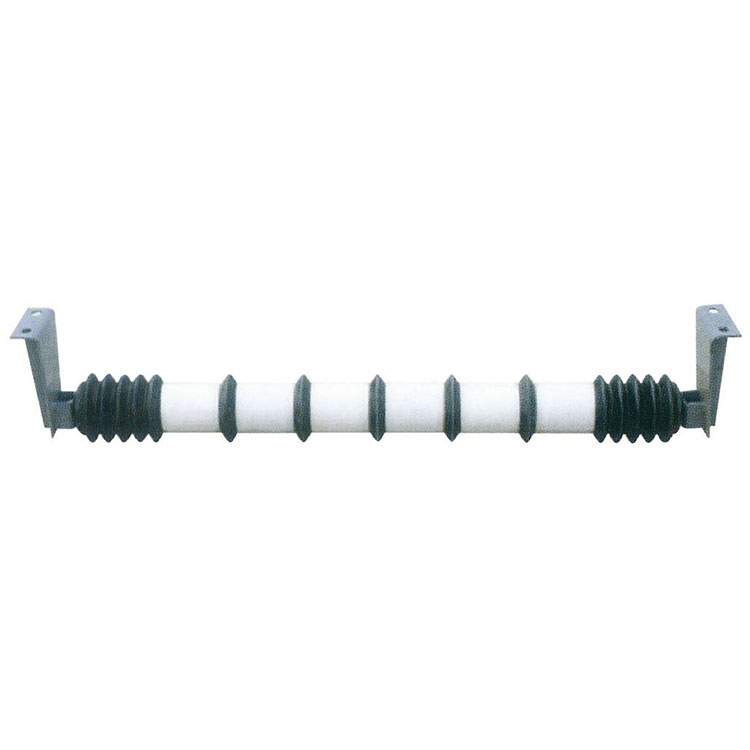

China Spiral Self Cleaning Idler Roller for Belt Conveyor Manufacturers, Suppliers, Factory

The corporate keeps to the procedure concept "scientific administration, premium quality and performance primacy, buyer supreme for Spiral Self Cleaning Idler Roller for Belt Conveyor,Spiral Return Idler,Spiral Return Idlers for Belt Conveyor,Steel Spiral Return Idler,Spiral Conveyor Idler Roller, Welcome any inquiry to our firm. We're going to be glad to establish pleasant business interactions with you!

Spiral Self Cleaning Idler Roller for Belt Conveyor, We strive for excellence, constant improvement and innovation, is committed to make us the "customer trust" and the "first choice of engineering machinery accessories brand" suppliers. Choose us, sharing a win-win situation!

Hot Products

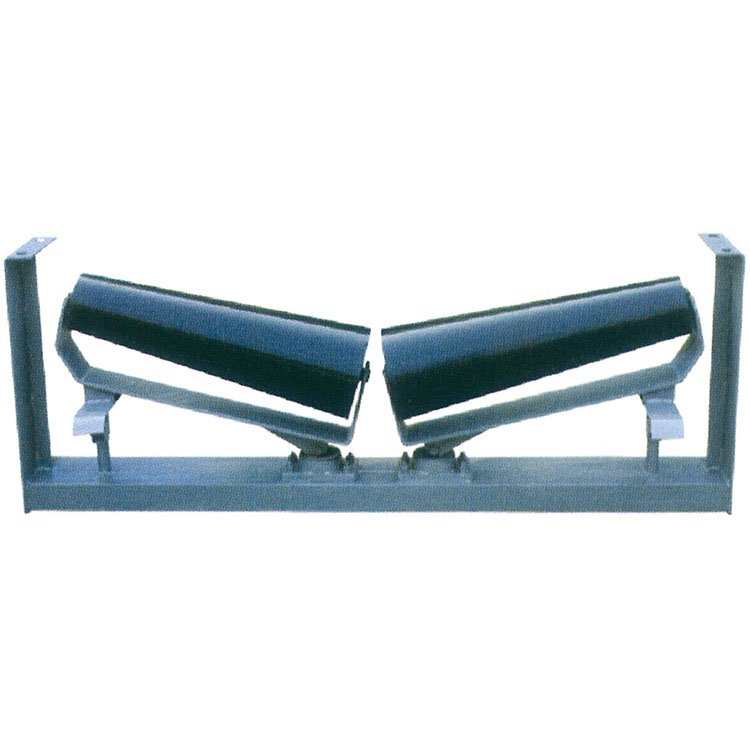

Rectangular Conveyor Transfer Chute

The Rectangular Conveyor Transfer Chute is mainly used on the head and tail of the belt conveyor to guide materials and prevent overflow. Rectangular Conveyor Transfer Chute is composed of structural parts, holders, guide skins, front curtains and rear curtains. The material belt is made of the same or more elastic material as the conveyor belt to protect the belt from damage and prevent material from overflowing and dust. Cooperate with front and rear curtains, dust removal system, etc. to effectively improve the production environment.Drum Pulley

The drum pulley is mainly used to fix the head drive of the belt conveyor. The surface can be covered with rubber, ceramic lagging, polyurethane coating, etc. to increase friction and wear resistance. Rubber patterns include diamond, V-shaped and other options. It is widely used in oil&gas, mining, sand and gravel, metallurgy, chemical industry, port and other industries.Conveyor Takeup Pulley

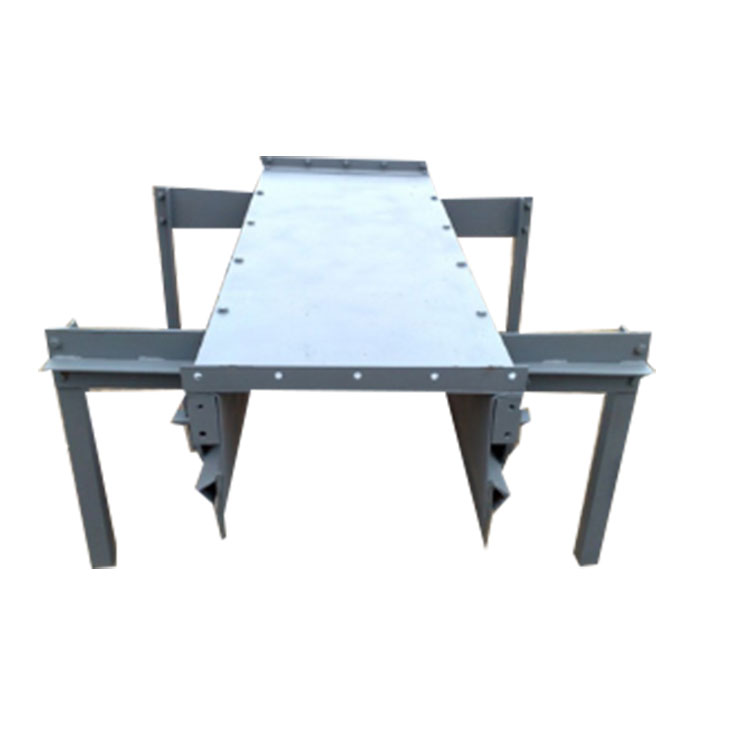

About conveyor takeup pulley, the large production line in the factory can process rollers with a diameter of up to 1 meter. The surface of the drum can be made of cast rubber, ceramic coating, polyurethane coating and other wear-resistant methods. Solving the problem of excessive wear under heavy hanging tensioning devices.Parallel Idler

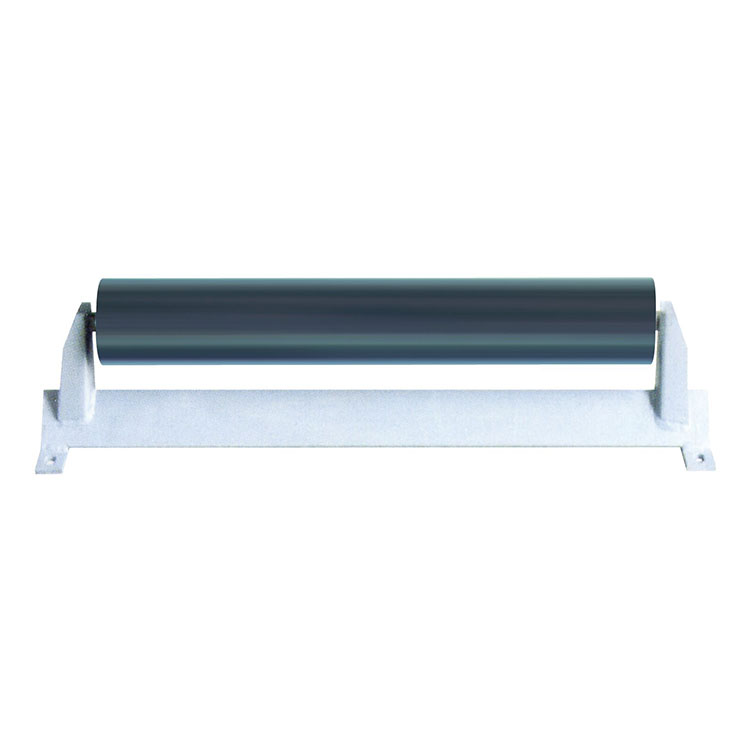

The main function of the parallel idler is to support the conveyor belt and the weight of the material, keep it in the correct and stable position, and reduce the friction between the conveyor belt and the idler, Reduce delivery costs and balance material during transportation.Polyurethane Belt Cleaner

Polyurethane Belt Cleaner are mainly used for cleaning the head belt of belt conveyor. It has the characteristics of high elasticity, acid and alkali resistance, flame retardant and antistatic. Widely used in belt cleaning of belt conveyors. The blade is made of polyether material, which is 50% more wear-resistant than ordinary polyurethane. The spring ensures automatic compensation in case of wear of the cutter head.Parallel Comb Idler

Parallel Comb Idler is one type of conveyor idler. It is made of high-frequency welded pipes, high-density nylon seals, comb-shaped rubber rings, spacers, bearings, and round steel. Parallel Comb Idler are mainly used to fix return belts of belt conveyors. The structural design has a self-cleaning function, which can effectively remove belt adhesive. It has the characteristics of low noise, thick tube wall, flexible rotation and low resistance.

Send Inquiry

X

We use cookies to offer you a better browsing experience, analyze site traffic and personalize content. By using this site, you agree to our use of cookies.

Privacy Policy