English

English 简体中文

简体中文  Esperanto

Esperanto  Afrikaans

Afrikaans  Català

Català  Cymraeg

Cymraeg  Galego

Galego  繁体中文

繁体中文  Latviešu

Latviešu  icelandic

icelandic  ייִדיש

ייִדיש  беларускі

беларускі  Hrvatski

Hrvatski  Kreyòl ayisyen

Kreyòl ayisyen  Shqiptar

Shqiptar  Malti

Malti  lugha ya Kiswahili

lugha ya Kiswahili  አማርኛ

አማርኛ  Bosanski

Bosanski  Frysk

Frysk  ភាសាខ្មែរ

ភាសាខ្មែរ  ქართული

ქართული  ગુજરાતી

ગુજરાતી  Hausa

Hausa  Кыргыз тили

Кыргыз тили  ಕನ್ನಡ

ಕನ್ನಡ  Corsa

Corsa  Kurdî

Kurdî  മലയാളം

മലയാളം  Maori

Maori  Монгол хэл

Монгол хэл  Hmong

Hmong  IsiXhosa

IsiXhosa  Zulu

Zulu  Punjabi

Punjabi  پښتو

پښتو  Chichewa

Chichewa  Samoa

Samoa  Sesotho

Sesotho  සිංහල

සිංහල  Gàidhlig

Gàidhlig  Cebuano

Cebuano  Somali

Somali  Тоҷикӣ

Тоҷикӣ  O'zbek

O'zbek  Hawaiian

Hawaiian  سنڌي

سنڌي  Shinra

Shinra  Հայերեն

Հայերեն  Igbo

Igbo  Sundanese

Sundanese  Lëtzebuergesch

Lëtzebuergesch  Malagasy

Malagasy  Yoruba

Yoruba  Español

Español  Português

Português  русский

русский  Français

Français  日本語

日本語  Deutsch

Deutsch  tiếng Việt

tiếng Việt  Italiano

Italiano  Nederlands

Nederlands  ภาษาไทย

ภาษาไทย  Polski

Polski  한국어

한국어  Svenska

Svenska  magyar

magyar  Malay

Malay  বাংলা ভাষার

বাংলা ভাষার  Dansk

Dansk  Suomi

Suomi  हिन्दी

हिन्दी  Pilipino

Pilipino  Türkçe

Türkçe  Gaeilge

Gaeilge  العربية

العربية  Indonesia

Indonesia  Norsk

Norsk  تمل

تمل  český

český  ελληνικά

ελληνικά  український

український  Javanese

Javanese  فارسی

فارسی  தமிழ்

தமிழ்  తెలుగు

తెలుగు  नेपाली

नेपाली  Burmese

Burmese  български

български  ລາວ

ລາວ  Latine

Latine  Қазақша

Қазақша  Euskal

Euskal  Azərbaycan

Azərbaycan  Slovenský jazyk

Slovenský jazyk  Македонски

Македонски  Lietuvos

Lietuvos  Eesti Keel

Eesti Keel  Română

Română  Slovenski

Slovenski  मराठी

मराठी  Srpski језик

Srpski језик

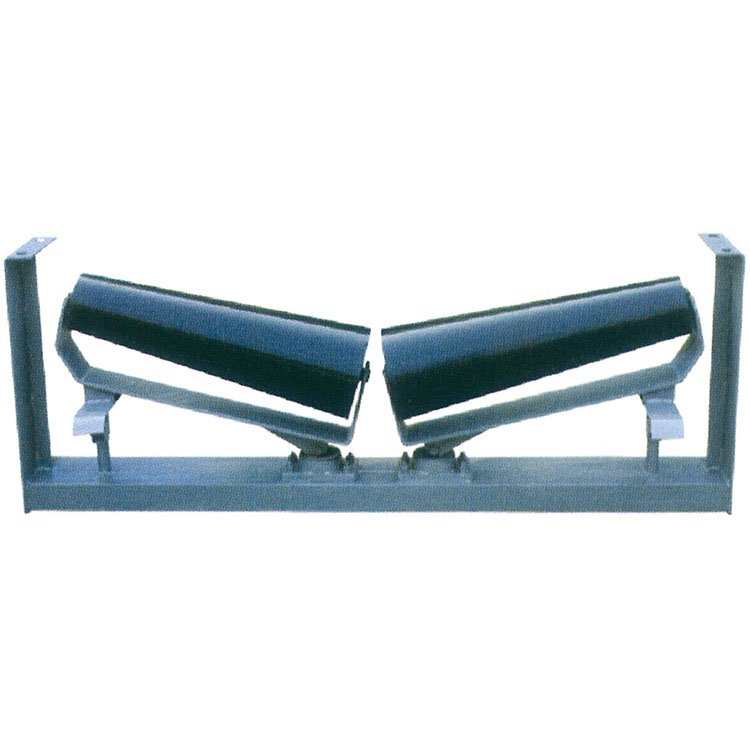

V-Shaped Bracket

Jiangsu Wuyun Transmission Machinery is a Chinese manufacturer specializing in belt conveyors. The V-shaped bracket design we produce allows the rollers to better contact the conveyor belt, providing more stable support and guidance. It is a good choice for advanced belt conveyor systems. In addition, we provide you with various models The V-shaped bracket can be customized according to the customer's size requirements, with affordable price and quality assurance.

Send Inquiry

V-shaped brackets originate from China's manufacturing base. Jiangsu Wuyun Transmission Machinery continues to develop and improve in the manufacturing of traditional machinery. We are more focused on the development of environmental protection and we use our creativity in the production of belt conveyors. Sufficient quantity and complete categories of production and inspection equipment provide guarantee for high-quality products. The V-shaped roller group is mainly used to support the empty section conveyor belt, and the distance between rollers is generally 3m. The V-shaped roller set has the function of preventing deviation. Generally, one V-shaped roller is placed every few parallel rollers, and the groove angle is generally 10°. Different raw materials are selected for production according to different product functions to ensure that the products produced can display important functions and functions when used. We not only wholesale V-type roller sets of various standard sizes, but also customize them according to customers' size requirements, with affordable prices and guaranteed quality.

The structural bracket of the V-shaped bracket has a bracket mounting hole at one end, and the multiple brackets in between form a parabolic V-groove. Their centers are through-mounted and bearing seats are installed at both ends of the spindle. These components are integrated as a whole. In this way, the conveyor roller frame required in the working conditions is formed. During installation, the bearing seat is first installed on the frame of the belt conveyor, and the conveyor belt is placed on the parabolic groove of the roller frame. , is a good choice for advanced belt conveyor systems.

V-shaped bracket product advantages:

1. A roller with a V-shaped notch. This design allows the roller to better contact the conveyor belt and provide more stable support and guidance;

2. Increase the friction between the roller and the conveyor belt to prevent the material from sliding or shifting and maintain the stability of the system;

3. Flame retardant, antistatic and aging resistant;

4. Super mechanical strength, can withstand repeated impact and vibration;

5. Excellent sealing performance, low noise, small rotation resistance, smooth operation and long service life;