English

English 简体中文

简体中文  Esperanto

Esperanto  Afrikaans

Afrikaans  Català

Català  Cymraeg

Cymraeg  Galego

Galego  繁体中文

繁体中文  Latviešu

Latviešu  icelandic

icelandic  ייִדיש

ייִדיש  беларускі

беларускі  Hrvatski

Hrvatski  Kreyòl ayisyen

Kreyòl ayisyen  Shqiptar

Shqiptar  Malti

Malti  lugha ya Kiswahili

lugha ya Kiswahili  አማርኛ

አማርኛ  Bosanski

Bosanski  Frysk

Frysk  ភាសាខ្មែរ

ភាសាខ្មែរ  ქართული

ქართული  ગુજરાતી

ગુજરાતી  Hausa

Hausa  Кыргыз тили

Кыргыз тили  ಕನ್ನಡ

ಕನ್ನಡ  Corsa

Corsa  Kurdî

Kurdî  മലയാളം

മലയാളം  Maori

Maori  Монгол хэл

Монгол хэл  Hmong

Hmong  IsiXhosa

IsiXhosa  Zulu

Zulu  Punjabi

Punjabi  پښتو

پښتو  Chichewa

Chichewa  Samoa

Samoa  Sesotho

Sesotho  සිංහල

සිංහල  Gàidhlig

Gàidhlig  Cebuano

Cebuano  Somali

Somali  Тоҷикӣ

Тоҷикӣ  O'zbek

O'zbek  Hawaiian

Hawaiian  سنڌي

سنڌي  Shinra

Shinra  Հայերեն

Հայերեն  Igbo

Igbo  Sundanese

Sundanese  Lëtzebuergesch

Lëtzebuergesch  Malagasy

Malagasy  Yoruba

Yoruba  Español

Español  Português

Português  русский

русский  Français

Français  日本語

日本語  Deutsch

Deutsch  tiếng Việt

tiếng Việt  Italiano

Italiano  Nederlands

Nederlands  ภาษาไทย

ภาษาไทย  Polski

Polski  한국어

한국어  Svenska

Svenska  magyar

magyar  Malay

Malay  বাংলা ভাষার

বাংলা ভাষার  Dansk

Dansk  Suomi

Suomi  हिन्दी

हिन्दी  Pilipino

Pilipino  Türkçe

Türkçe  Gaeilge

Gaeilge  العربية

العربية  Indonesia

Indonesia  Norsk

Norsk  تمل

تمل  český

český  ελληνικά

ελληνικά  український

український  Javanese

Javanese  فارسی

فارسی  தமிழ்

தமிழ்  తెలుగు

తెలుగు  नेपाली

नेपाली  Burmese

Burmese  български

български  ລາວ

ລາວ  Latine

Latine  Қазақша

Қазақша  Euskal

Euskal  Azərbaycan

Azərbaycan  Slovenský jazyk

Slovenský jazyk  Македонски

Македонски  Lietuvos

Lietuvos  Eesti Keel

Eesti Keel  Română

Română  Slovenski

Slovenski  मराठी

मराठी  Srpski језик

Srpski језик

China Electric Actuated One Side Plow Unloader Manufacturers, Suppliers, Factory

continue to enhance, to be certain solution top quality in line with market and buyer standard requirements. Our corporation has a excellent assurance program are actually established for Electric Actuated One Side Plow Unloader,Conveyor Diverter Plows Material Diversion Ploughs,Centering Device for Conveyor Divert Plow,Belt Conveyor Diverter Plow,V plough feeder, We are looking forwards to establishing long-term business relationships with worldwide customers.

Electric Actuated One Side Plow Unloader, To achieve reciprocal advantages, our company is widely boosting our tactics of globalization in terms of communication with overseas customers, fast delivery, the best quality and long-term cooperation. Our company upholds the spirit of "innovation, harmony, team work and sharing, trails, pragmatic progress". Give us a chance and we'll prove our capability. With your kind help, we believe that we can create a bright future with you together.

Hot Products

V-Plow Diverter

V-Plow Diverter is mainly used for multi-point double-side unloading of belt conveyors. It has the characteristics of convenient electric control and fast and clean discharge. The parallel arrangement of roller groups ensures smooth belt operation with minimal damage, and the platform can be raised and lowered to allow multiple points on a conveyor line to discharge materials to both sides of the conveyor. The plowshare is made of polymer material, which has low wear and does not damage the belt. Widely used in the transportation of materials with smaller particle sizes such as electricity, coal transportation, construction, and mining.Drive drum pulley

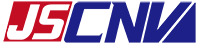

Drive drum pulley is mainly used for the head drive of belt conveyors. It has the characteristics of compact structure, small space occupation, easy installation, high protection, low cost, dustproof and waterproof. The surface can be covered with rubber, ceramic lagging, polyurethane coating, etc. to increase friction and wear resistance. It is widely used in oil&gas, mining, sand and gravel, metallurgy, chemical industry, port and other industries.One-Line Cleaner

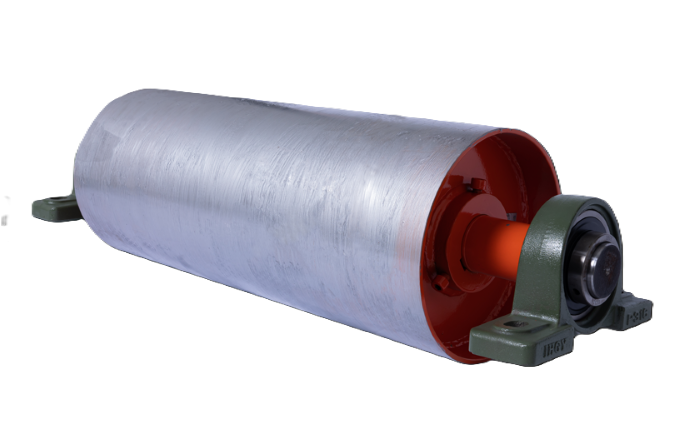

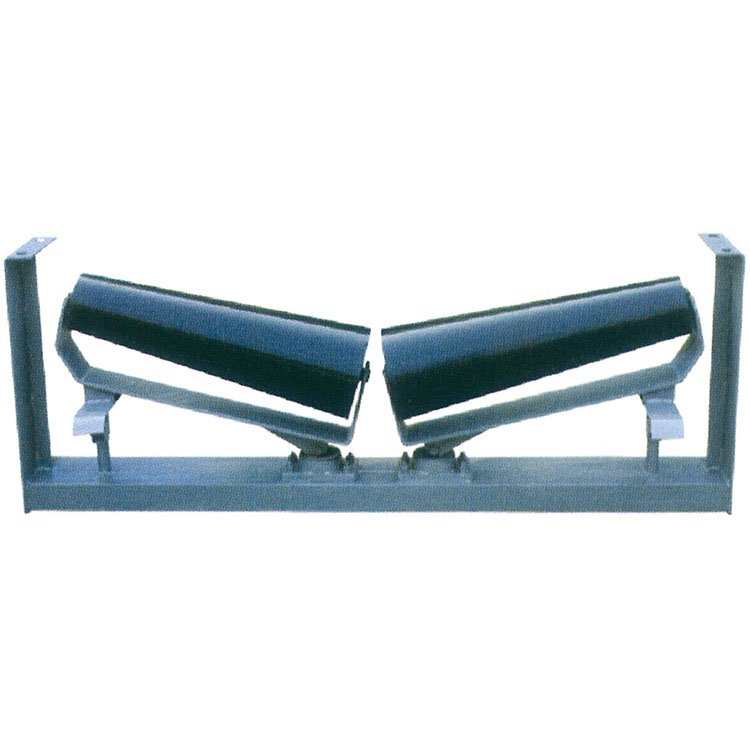

One-line cleaner is for the return belt cleaning. It is mainly used in front of the rear bend pulley and in front of the heavy vertical tensioning device of the belt conveyor. It can especially be used to clean the empty section of the two-way running belt. It has the characteristics of acid and alkali resistance, flame retardant and antistatic, high wear resistance, and does not damage the belt. The blade is made of high-strength polyurethane, the V-shaped design ensures belt cleanliness, and the automatic gravity design ensures automatic-compensation when the blade wears out.Conveyor Idler Bearings

During the use of Conveyor Idler Bearings, if pay attention to the following points, it will be very helpful to improve the service life and operating efficiency:A. Ensure the good working effect of the return cleaner. Once the stain on the return belt sticky to the Conveyor Idler Bearings, the outer circle of the roller will no longer be uniform, causing the belt to jump, thereby damaging the idler bearing.Electric Rotary Brush Belt Cleaner

Jiangsu Wuyun is a China manufacturer specializing in belt conveyors. We offer you various types of Electric Rotary Brush Belt Cleaner.Discover unparalleled excellence in transmission and conveying machinery with Jiangsu Wuyun – where two decades of innovation, a commitment to quality, and a focus on energy-saving solutions converge to elevate your operational efficiency. Partner with us for cutting-edge products that redefine industry standards.Ordinary Conveyor Idler

High quality Ordinary Conveyor Idler is offered by China manufacturer Jiangsu Wuyun Transmission Machinery Co., Ltd. who is a China manufacturer specializing in belt conveyors. The rollers manufactured by Wuyun have the characteristics of thick tube wall, flexible rotation and low resistance. Widely used in belt conveyor belts and material support.