English

English 简体中文

简体中文  Esperanto

Esperanto  Afrikaans

Afrikaans  Català

Català  Cymraeg

Cymraeg  Galego

Galego  繁体中文

繁体中文  Latviešu

Latviešu  icelandic

icelandic  ייִדיש

ייִדיש  беларускі

беларускі  Hrvatski

Hrvatski  Kreyòl ayisyen

Kreyòl ayisyen  Shqiptar

Shqiptar  Malti

Malti  lugha ya Kiswahili

lugha ya Kiswahili  አማርኛ

አማርኛ  Bosanski

Bosanski  Frysk

Frysk  ភាសាខ្មែរ

ភាសាខ្មែរ  ქართული

ქართული  ગુજરાતી

ગુજરાતી  Hausa

Hausa  Кыргыз тили

Кыргыз тили  ಕನ್ನಡ

ಕನ್ನಡ  Corsa

Corsa  Kurdî

Kurdî  മലയാളം

മലയാളം  Maori

Maori  Монгол хэл

Монгол хэл  Hmong

Hmong  IsiXhosa

IsiXhosa  Zulu

Zulu  Punjabi

Punjabi  پښتو

پښتو  Chichewa

Chichewa  Samoa

Samoa  Sesotho

Sesotho  සිංහල

සිංහල  Gàidhlig

Gàidhlig  Cebuano

Cebuano  Somali

Somali  Тоҷикӣ

Тоҷикӣ  O'zbek

O'zbek  Hawaiian

Hawaiian  سنڌي

سنڌي  Shinra

Shinra  Հայերեն

Հայերեն  Igbo

Igbo  Sundanese

Sundanese  Lëtzebuergesch

Lëtzebuergesch  Malagasy

Malagasy  Yoruba

Yoruba  Español

Español  Português

Português  русский

русский  Français

Français  日本語

日本語  Deutsch

Deutsch  tiếng Việt

tiếng Việt  Italiano

Italiano  Nederlands

Nederlands  ภาษาไทย

ภาษาไทย  Polski

Polski  한국어

한국어  Svenska

Svenska  magyar

magyar  Malay

Malay  বাংলা ভাষার

বাংলা ভাষার  Dansk

Dansk  Suomi

Suomi  हिन्दी

हिन्दी  Pilipino

Pilipino  Türkçe

Türkçe  Gaeilge

Gaeilge  العربية

العربية  Indonesia

Indonesia  Norsk

Norsk  تمل

تمل  český

český  ελληνικά

ελληνικά  український

український  Javanese

Javanese  فارسی

فارسی  தமிழ்

தமிழ்  తెలుగు

తెలుగు  नेपाली

नेपाली  Burmese

Burmese  български

български  ລາວ

ລາວ  Latine

Latine  Қазақша

Қазақша  Euskal

Euskal  Azərbaycan

Azərbaycan  Slovenský jazyk

Slovenský jazyk  Македонски

Македонски  Lietuvos

Lietuvos  Eesti Keel

Eesti Keel  Română

Română  Slovenski

Slovenski  मराठी

मराठी  Srpski језик

Srpski језик

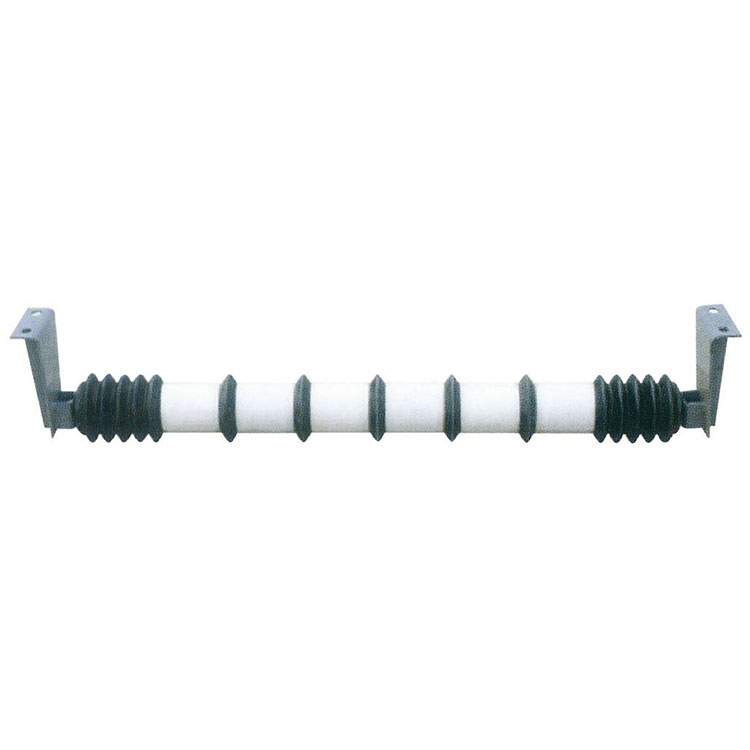

China Self Aligning Friction Idler for Belt Conveyor Manufacturers, Suppliers, Factory

In China, Wuyun is distinguished among manufacturers and suppliers. Our factory provides Conveyor Idler Bracket, Conveyor Belt Cleaner, Conveyor Idler, etc. Extreme design, quality raw materials, high performance and competitive price are what every customer wants, and that's also what we can offer you. We take high quality, reasonable price and perfect service.

Hot Products

Drum Pulley

The drum pulley is mainly used to fix the head drive of the belt conveyor. The surface can be covered with rubber, ceramic lagging, polyurethane coating, etc. to increase friction and wear resistance. Rubber patterns include diamond, V-shaped and other options. It is widely used in oil&gas, mining, sand and gravel, metallurgy, chemical industry, port and other industries.Unpowered Rotary Brush Belt Cleaner

There are two chain transmission devices at both ends of the unpowered rotary brush belt cleaner, which can transfer the friction generated by the belt and the idler to the brush shaft, causing the brush to rotate in the opposite direction to the belt movement. Achieve the effect of cleaning the belt. It has the characteristics of energy saving, environmental protection, easy installation and space saving.Conveyor Takeup Pulley

About conveyor takeup pulley, the large production line in the factory can process rollers with a diameter of up to 1 meter. The surface of the drum can be made of cast rubber, ceramic coating, polyurethane coating and other wear-resistant methods. Solving the problem of excessive wear under heavy hanging tensioning devices.H Type Conveyor Belt Cleaner

H Type Conveyor Belt Cleaner is mainly used for cleaning the head belt of belt conveyors. It has the characteristics of high wear resistance, long use time and good cleaning effect. The tungsten carbide alloy cutter head and abrasion-resistant coating make the alloy cleaner suitable for a variety of corrosive materials without damage. When used with a secondary cleaner, the cleaning effect is even better. The built-in folding design and the installation method 15⁰ below the center line can effectively avoid the impact of oversized materials.V-Plow Diverter

V-Plow Diverter is mainly used for multi-point double-side unloading of belt conveyors. It has the characteristics of convenient electric control and fast and clean discharge. The parallel arrangement of roller groups ensures smooth belt operation with minimal damage, and the platform can be raised and lowered to allow multiple points on a conveyor line to discharge materials to both sides of the conveyor. The plowshare is made of polymer material, which has low wear and does not damage the belt. Widely used in the transportation of materials with smaller particle sizes such as electricity, coal transportation, construction, and mining.Double Sealed Conveyor Transfer Chute

Double Sealed Conveyor Transfer Chute is mainly used at the head and tail of the belt conveyor to guide, prevent overflow and dust-proof materials. Double Sealed Conveyor Transfer Chute is composed of structural parts, holders, skirt panels, front curtains and rear curtains. The anti-overflow skirt adopts an integrated structure. The straight part prevents materials from overflowing and blocks most dust. The everted skirt plate is close to the conveyor belt to prevent all dust from escaping. In conjunction with a negative pressure dust removal system, a dust-free working environment can be achieved.

Send Inquiry

X

We use cookies to offer you a better browsing experience, analyze site traffic and personalize content. By using this site, you agree to our use of cookies.

Privacy Policy